Testers/Testing

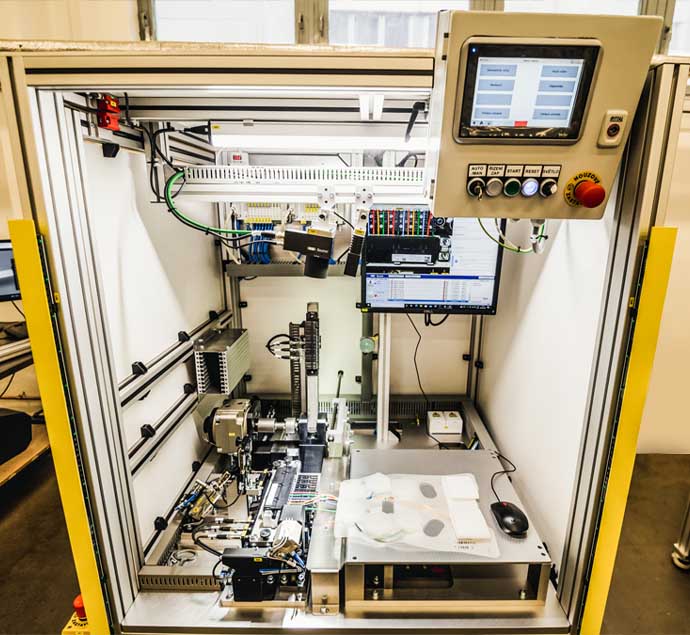

We design testing equipment tailored to specific applications. Our testers are equipped with advanced measuring technology, enabling precise and reliable measurement of electrical, mechanical, and fluid parameters. By integrating modern technologies such as Poka-Yoke (error prevention) and subsequent product labeling, we help our customers ensure high production quality and minimize the risk of defects.

Our solutions include:- Leak Testing Stations

Equipment for checking product tightness, ensuring reliability and safety.

- End-of-Line (EOL) Testers

Comprehensive systems for final functionality testing of products at the end of production lines.

- Force Measurement Stations

Precision tools for measuring forces required for operating mechanical components, ensuring proper functionality and ergonomics.

- Camera Systems for Part Presence or Code Reading (2D, 3D)

Automated visual inspections to detect missing components, incorrect labeling, or surface defects.

- Precision and Reliability

We use state-of-the-art measuring technologies to deliver accurate and consistent results.

- Integration with Production Processes

Our testers are designed to seamlessly fit into existing production lines and systems.

- Increased Efficiency and Quality

Automated testing processes reduce human error and boost productivity.

- Modular and Flexible Solutions

Easily adaptable to new requirements or product changes.

- With our expertise and technical knowledge,

we offer comprehensive testing solutions that help our customers ensure top-quality products, enhancing their competitiveness in the market.